- ESPRIT CAM SYSTEM

-

-

ESPRIT CAM System

ESPRIT is a high-performance, full-spectrum Computer-Aided Manufacturing (CAM) system for a full range of machine tool applications.

OEM-endorsed ESPRIT drives machine tools in over 15,000 shops across the globe. Comprehensive in its ability to handle today's most advanced machines, ESPRIT satisfies even the most demanding programmers and machining applications. ESPRIT is preferred by CNC programmers worldwide, in every advanced manufacturing sector− from medical to aerospace. ESPRIT is the right choice for programmers, manufacturers, and machinists looking to fully exploit their machine tool investment and enjoy the unparalleled freedom of advanced technology.

Copyright © 2012-2016 DP TECHNOLOGY CORP.

-

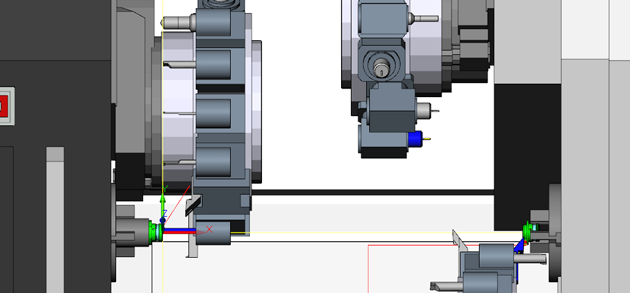

Program Any Machine Tool

The high-performance ESPRIT system offers powerful programming for any CNC machine tool. ESPRIT's full-spectrum functionality includes programming for:

2−5 Axis Milling

2−22 Axis Turning

2−5 Axis Wire EDM

Multitasking Mill-Turn Machining

B−Axis Machine Tools

Copyright © 2012-2016 DP TECHNOLOGY CORP.

-

Machine Any Part Geometry

ESPRIT’s seamless CAD to CAM interface directly imports any native part model from any source, fully intact, with no need for programmers to edit or rebuild geometry. Starting with 100% complete and accurate part geometry eliminates nearly all of the difficulty in programming complicated parts and dramatically reduces programming time.

Directly model or machine any part geometry powered by:

Parasolid Solid Modeler

ACIS Solid Modeler

NURBS Surface Modeler

STL Modeler

SD/3D wire frame modeler

Drawing, dimensioning, and annotation

Out of the box, ESPRIT reads data from the following native formats:

ACIS (SAT)

AutoCAD (DWG)

CSV

DXF

IGES

Mechanical Desktop

TXT

VDA-FS

Parasolid (X_B, X_T)

Autodesk Inventor (*.ipt, *.iam), with feature exchange

Solid Edge (*.par, *.psm, *.asm), with feature exchange

SolidWorks (*.sldprt, *.sldasm), with feature exchange

ESPRIT offers the following data readers as options:

ACIS (SAT)

AutoCAD (DWG)

CSV

DXF

Autodesk Inventor

IGES

Mechanical Desktop

Parasolid (X_B, X_T)

Copyright © 2012-2016 DP TECHNOLOGY CORP.

-

- Solid Simulation

-

Dynamic Solid Simulation and Verification

Real-Time Simulation

Synchronized, solid simulation. View entire part on-screen, complete with key moving elements and machining environment− machine tool, fixtures, clamps, stock, and workpiece.

Machine With Confidence

Gain complete confidence in your machining processes with ESPRIT as you compare accurately rendered "as designed" versus "as machined" parts.

Collision Detection

Comprehensive, realistic, and accurate, ESPRIT's exhaustive verification guards against potential crashes and eliminates the need for expensive dry runs.

High Performance

Minimize downtime, maximize manufacturing efficiency, and cut machining costs by correctly machining, even the most complex parts, the first time.

Copyright © 2012-2016 DP TECHNOLOGY CORP.

- KnowledgeBase

-

KnowledgeBase

KnowledgeBase expands the productivity and automation capabilities of ESPRIT. By providing a single source for all your shop floor data, KnowledgeBase improves efficiency, consistency, and quality of machining operations.

Advanced Adaptive Machining

Adapts to Varying Part Geometry

Automates Engineering Changes

Adapts to Part Families

Automated Feature Recognition

Copyright © 2012-2016 DP TECHNOLOGY CORP.

- Universal Post Processing

-

Universal Post Processing

ESPRIT’s universal post processor effortlessly creates the high-quality G-code you need to fully exploit your machine tool investment.

Post Processors Library

With ESPRIT you get proven out-of-the-box operation with a complete library of pre-defined post processors.

Factory-Certified Post Processors

Additional factory-certified posts are available for many of the leading machine tool brands.

Customizations

ESPRIT’s open architecture allows you to easily adjust any post processor to suit your personal preferences and shopfloor requirements.

Flawless G-Code

Maximum machine utilization and optimal part quality at the lowest possible cost.

Copyright © 2012-2016 DP TECHNOLOGY CORP.

- Technical Information

-

Technical Information

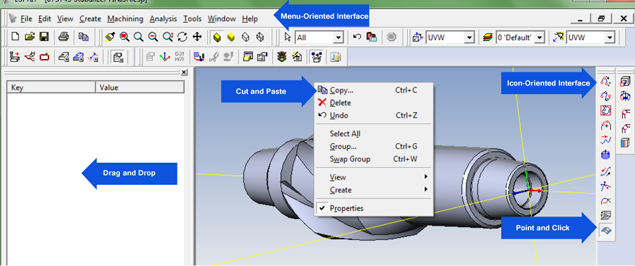

100% Pure Windows Application

Built from the ground up to run on the Windows platform, ESPRIT is designed to get you working faster, better, and more productively than ever before. ESPRIT has the look and feel you would expect from a genuine Windows-based application, and the functionality you need for optimal performance.

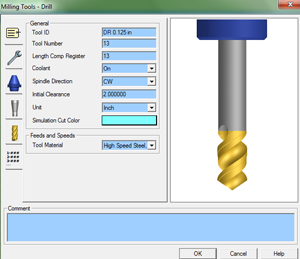

Tool Kit

The ESPRIT Tool Kit is composed of ESPRIT’s Application Programming Interface (API) — based on the Microsoft Component Object Model (COM) — and Microsoft Visual Basic for Applications (VBA), an embedded technology that gives you the power to write macros to automate a variety of programming tasks. The ESPRIT API provides third party access to the vast array of CAD/CAM technology built into ESPRIT.

Copyright © 2012 DP TECHNOLOGY CORP.

Copyright © 2016 SHAPE DESIGN TECHNOLOGIES, INC.